The Team

Peter Brady

Peter was born in Dunedin, New Zealand in 1957. His interest in boats began as early as he can remember with his father building models of the Royal Navy ships he had served on during the Second World War. It continued throughout his childhood, being one of 5 boys and 2 girls who shared the families fleet of canoes, sailing dinghy’s and a 14ft long putt-putt boat “Chug-a-lug” in which they explored the harbour, followed his older brothers dinghy racing and even once ventured out to sea through Taiaroa Heads.

Peter interest in boat design began as a 13 year old, forming model yachts out of blocks of foam plastic with bits of umbrellas for the mast and sails, then racing them against his brothers under a set of class rules they worked out. An avid reader he studied any books on the subject and boats in general he could get his hands on including Janes Fighting Ships from 1900 to the 1950’s a great deal of which he can still remember to this day.

Just after he turned 15 the family suffered a tragedy when his oldest brother Steven was lost at sea, crayfishing on the dangerous West Coast of the South Island, which instead of scaring Peter off boats, instilled in him a lifelong desire to design and build good strong, safe boats. Five months later having obtained his School Certificate and after spending 3 weeks over Christmas on the West Coast crayfishing where his brother was lost, Peter began a boat-building apprenticeship at the highly respected boat-building yard of Miller & Tunnage having also been accepted to study architecture at the Dunedin Polytechnic. The decision to enter the design world from the hands on trade rather than classroom based drawing experience (there was no formal training for Naval Architects in New Zealand at that time) forged the way he has approached the design profession to this day.

Peter has always considered himself very lucky to have come through what is considered one of the best boat-building training systems in the world as it also has a strong design based emphasis. He was even luckier in that he did it at a time when New Zealand wooden boat-building and its designer-boat-builders such as Jim Young, John Spencer, John Lidgard and his tutor at the Auckland Technical College Alan Wright were at their peak and young designers such as Bruce Farr and Ron Holland were just starting to make their mark. Having started his apprenticeship in one of the last traditional wooden boat-building workshops Peter learn both the old boat-building methods and their history plus was involved in the yards transition to cold moulding and laminated construction.

It was also around this time that Peter had his first introduction to multihulls, crewing on an Arthur Piver designed 37ft racing trimaran called Tactile Too that had been heavily modified by its builders the Cook brothers. During his yearly visits to Auckland Technical College Alan Wright must have seen some potential in Peter as he was very encouraging of his ambition to be a designer however nearing the end of his apprenticeship Peter wasn’t so sure and so spent a couple of years trying different aspects of the building trade, getting married to Lorma, and working on a farm. The lure of boats was however too much and so at the time their first child was born Peter returned to the boat-building industry and started his own business. He then went into partnership with his brother Jim who came from a GRP background teaching each other their respective skills on a number of restoration and new build projects. These projects included restoring the 29ft double ended power boat “Florence” that was built around 1910 and turning it into a line boat for the Port Chalmers wharfs with the ability to beam trawl for blue spanner crabs.

Peter and Jim also constructed a new wheelhouse for the fishing vessel “Tikianga” and rebuilt the fishing vessel “Jean” which had sunk after an altercation with a channel marker and fitting her with a new wheelhouse constructed in FRP of a flat panel an experience which was to lead to Peter’s development of the P.A.C.K. System many years later.

It was during this time that Peter’s interested in developing new boat-building technology really took hold as he learnt more about GRP and the economics of boat-building.

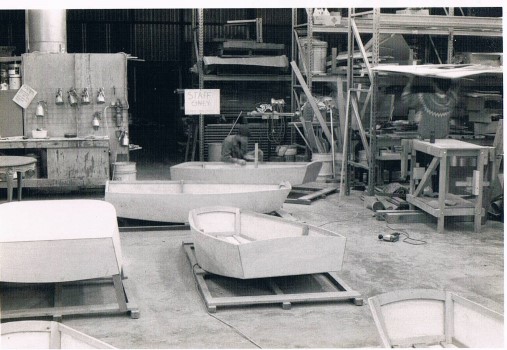

1980 saw the overnight introduction of a 20 sales tax on boatbuilding and the near obliteration of the New Zealand boat-building industry. It is estimated that somewhere around 80% of boat-builders left New Zealand at this stage with Peter, Lorma and their now 2 children moving to Brisbane Australia where he and his brother gained work modifying the moulds for one of the first large production catamarans, the Stratus 12.

After a year of finding his feet in this new country he then returned to working for himself undertaking repairs, fit outs, restorations including a major project on the 60ft Millkraft powerboat “Silver Mist” and setting up a private boat-building school.

He received his first commission for a new build in 1986 with Lorma joining him when their children were at school and then his first design and build commission for a 42ft motorsailing catamaran “Centurion” the next year. They both took a break from the industry in 1990 after Peter suffered a reaction to epoxy in his throat and Lorma broke her leg badly playing soccer. They toured around Queensland home schooling their teenage children in a caravan whilst Peter taught himself computer drafting, began writing articles for magazines and developed a number of designs including sharpies and the Campa Cat series of trailerable catamarans.

Upon returning to Brisbane, Peter and Lorma threw themselves back into the industry, designing more sailing and motorsailing catamarans, project managing, teaching boat-building and design and then ultimately back into setting up their own boat-building shed to build the 41ft motorsailer “James Scheerer” for scientific research in Shark Bay in Western Australia. With their children at high school Lorma joined Peter full time becoming a respected high tech laminator and marine interior decorator in her own right. Peter and Lorma later trained both their children as boat-builders with their daughter Chloe still a partner in the family business to this day running the office. In 1992-3 Peter designed his first power catamaran “Freeway” and he has been designing and building them continuously since with over 120 of his designs on the water 40 plus that he has built.

He coined the name “displaning” to describe his hull type that operates economically seamlessly between displacement and planing speeds and has been continuously refining the type for the last 24 years obtaining fuel efficiencies that are considered “world’s best practice”. In 1995 Peter designed the Scimitar 1010 for Scimitar Marine building the plug, moulds and the first 8 boats before Scimitar Marine took over the building. The Scimitar 1010 was an absolute breakthrough in power catamaran design winning the BIA’s “Cruiser of the Year” in 1997 and it is a tribute to Peter’s design skills that only 2 minor changes were made to the design on the next 58 boats built.

Managing director of Pacific Power Catamarans

In 1998 Peter started developing his P.A.C.K. (Prefabricated. Assembly. Component. Kit.) Boatbuilding System with the construction of “Dolphin Wild” (now Mahi Mahi) a 40ft eco-tourism power catamaran that is still in service today. He had always had a strong interest in boatbuilding systems starting with the construction of a wheelhouse from moulded flat panels in 1980 for the fishing vessel “Jean” whilst still in New Zealand and he has continued his development of the system both through boats he has built himself and by licencing its use to both professionals and amateur boatbuilders to this day. At least 26 power catamarans up to 64ft have been built using variations of the system with constant improvements being made each time. As a designer- builder Peter has been able to both control the process and personally analyse the results and so has been able to adapt and improve the system very quickly to take advantage of other developments in moulding techniques such as infusion. The first 4 P.A.C.K. System boats were built to the USL Code as have been another 6 since so the principles have been examined and tested by a number of engineers and naval architects in 5 states. One of the vessels built in 2000 has been 21/2 times around Australia and the very first vessel constructed using the system has been in continuous service since 1998 so the construction system has been well and truly tested.

Having designed and built 14 flybridge power catamarans between 11.2 and 12.2m in length under the Leopard Power Cats name between 2001 and 2004 Peter then put Leopard Power cats custom boatbuilding on hold for 3 years taking 4 more orders into partnership with one of clients to develop a production version to be called the Brava 42 that was later lengthened to 45ft. Peter as managing director oversaw the design and construction of every part of the business including the purpose built shed. 15 boats were built by Brava Marine during Peter’s management including a fisheries patrol boat version for the Queensland Government and the design’s excellence was recognised by the industry with the awarding of the 2008 Judges Innovation Award from the BIA.

In 2008 Peter returned to designing and building custom power cats with 7 boats ranging between 41 to 58ft in the water or under construction to date. During this time Peter and Pacific Power Cats have also undertaken a large variety of other work including modifying a number of his power catamarans, undertaking the major refit of a timber Griffin 32 “Nimmitabel” and the alterations to the 100ft maxi “Wild Thing”.

Over his boatbuilding career Peters experience includes surveying, teaching, building, restoration and repairs of both traditional and modern wooden boats, interior fit outs, composite production boatbuilding including plugs and moulds, custom composite new builds and repairs, construction and repair of composite structures including carbon-fibre masts, spreaders, booms, chainplates and beams. From this experience Pacific Power Cats are able to undertake any of these tasks with confidence with many of their employees trained by Peter and others bringing the experience of working on Volvo 70’s, maxis, Americas Cup boats and Wally’s. In 2015 Peter started the work on developing a modular construction system for decks and cabins called DECKIT which was prototyped on the Offshore 45 “Piera” having been tested and certified to Lloyds Composite Rules for commercial vessel operations under AMSA. On this vessel he also introduced the use of Crestomer 1152PA an acrylic modified polyurethane glue to bond all the deck structure together and all the internal structural elements such as bulkheads and partitions into the boat rather than using traditional FRP tabbing.

Over his career Peter has spent thousands of hours at sea both driving his own designs, cruising and ocean racing having competed in 3 Sydney to Hobarts (including a class win in 2000), 8 Brisbane to Gladstone’s (including multihull handicap win as navigator), 2 Hayman Island Big Boat series and 2 Hamilton Island series. Lorma accompanied Peter on many of these races including 1 Sydney to Hobart and many delivery trips. Over his career Peter has picked up 2 national industry awards for his power catamaran designs, Cruiser of the Year 1997 for the Scimitar 1010 and Judges Innovation Award in 2007 for the Brava 45 and was one of three judges of the System Three Modern Boating International Design Competition 1994. Peter is one of the few designer-boatbuilders still operating and is still actively involved in developing new technologies and boatbuilding techniques.

Lorma Brady

Lorma Brady joined Peter as his trades assistant in 1986 when their children started school and has worked alongside him ever since. During this time she has specialised in composites laminating and having completed an interior decorating course, has undertaken this role for the business on the 40 plus boats they have built as well other outside marine projects.

Besides being involved in the construction of all they boats they have built the boats Lorma has also constructed and repaired carbon fibre masts, booms, fore beams, chain plates and a huge variety of composites structures including being involved in the lengthening of the 100ft maxi “Wild Thing”.

Lorma has been involved with the development of infusion techniques for the past 11 years and now teaches their new employees alongside making components for the boats they have under construction.

She has completed around 8,000nm at sea on delivery trips for their boats plus offshore sailing and racing including a Sydney to Hobart class win in 2000, five Brisbane to Gladstone races’s and a Hamilton Island Series. Lorma has been able to bring a unique women’s perspective to Peters design work both from the experience at sea and her knowledge of what women want on a boat.

Chloe Knott

Chloe Knott has grown up in the world of boat-building for as long as she can remember whether it was sailing on boats on weekends with the family or playing after school on whatever boat Peter and Lorma were building. Chloe started her boat-building apprenticeship in the family business when she completed high school and then worked overseas in hotel front office administration whilst traveling, learning sales skills and management. She re-joined the family business at Leopard Power Cats in 2004 to run the office and help out in workshop when needed and continued with the family joint venture of Brava Marine where she ended up Administration Manager of Payroll, HR and Front Office.

When the family business returned to custom boat-building in 2008, Chloe took over all administration and continued working with Peter, learning contracting and costings skills again helping out on the floor undertaking any boat-building tasks when an extra hand was needed. Chloe now has 3 young children of her own and now runs the company administration from either the workshop or from her home office and is also becoming more involved in the interior decoration with Lorma and sales side of the business with Peter.